Table of Contents

Shell & Tube Oil Cooler Manufacturer in Karnataka

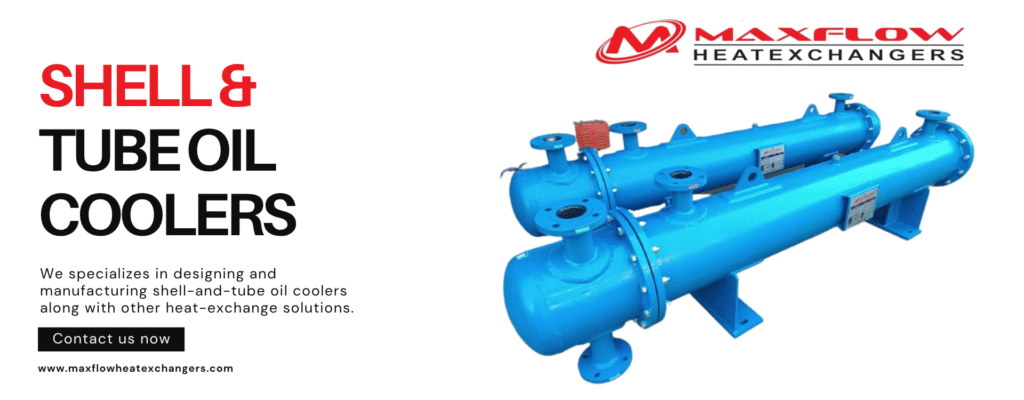

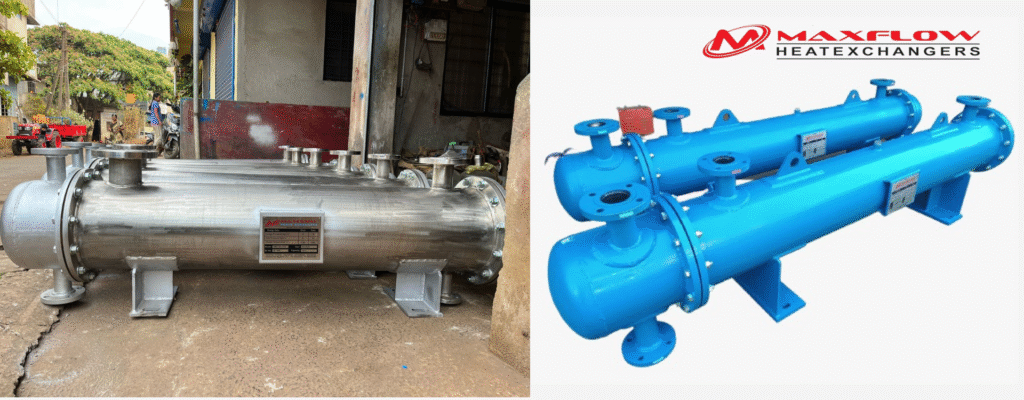

In the industrial heartland of Karnataka, one company is carving out a strong reputation in the field of thermal management: Maxflow Heat Exchangers. Based in Belgaum, it specializes in designing and manufacturing shell-and-tube oil coolers along with other heat-exchange solutions. Operating under the banner of precision, quality and responsiveness, Maxflow is becoming a go-to for industries requiring reliable oil-cooling systems.

Company Snapshot

- Maxflow Heat Exchangers is located in Belgaum (also written Belagavi), Karnataka, India. maxflowheatexchangers.com

- They are ISO 9001:2015 certified. maxflowheatexchangers.com

- The company began operations around 2022, building on a heat‐exchanger manufacturing background. maxflowheatexchangers.com

- Product portfolio includes: Shell & Tube Oil Coolers, Plate Type Heat Exchangers, Air Oil Coolers, Condensers, Tube Bundles, Steam Radiators (Dryers) and more. maxflowheatexchangers.com

Why Shell & Tube Oil Coolers Matter

In many industrial applications—hydraulic systems, lubrication circuits, turbines, compressors—oil must be cooled efficiently. Shell & tube oil coolers provide an effective way to transfer heat from oil to another medium (often ambient air or a secondary fluid). Key benefits include:

- Robust construction suited for high pressures and temperatures

- Good heat transfer area and flow control

- Versatility in oil‐type, flow rate, materials, and configuration

For industries in Karnataka and across India, having a local manufacturer capable of customizing shell & tube oil coolers means shorter lead times, localized service and adaptability to regional power and environmental conditions.

Maxflow’s Key Strengths

- Localization: Being based in Karnataka (Belgaum) means proximity to many manufacturing hubs in southern and western India.

- Customization: According to their website, they design both standard and bespoke models to meet customer needs. maxflowheatexchangers.com

- Quality & Certification: ISO 9001:2015 certification gives confidence in consistent manufacturing processes.

- Comprehensive portfolio: They’re not just doing oil coolers but a range of heat exchangers, which suggests broader engineering depth.

- Service & Support: They mention on-site/off-site servicing for installed units. maxflowheatexchangers.com

Applications & Industries Served

Maxflow’s shell & tube oil coolers are applicable in many sectors:

- Hydraulic power packs, hydraulic presses

- Lubrication systems for large rotating equipment

- Machine tools and industrial manufacturing equipment

- Mobile hydraulics (construction, cranes, etc)

- Wind power, rail technology, iron & steel, chemical plants maxflowheatexchangers.com

Why Choose Maxflow – From a Buyer’s Perspective

If you’re an engineer or procurement manager looking for oil‐cooler solutions, here’s why Maxflow could be a strong partner:

- Customization: Get a solution tailored to your oil type, flow rate, temperature drop, space constraints.

- Local manufacturing: Reduced logistics cost, easier visits, quicker after‐sales support.

- Quality assurance: Their claims of ISO certification and site/off‐site servicing are promising.

- Competitive pricing: They advertise “premium – but affordable” offerings. maxflowheatexchangers.com

- Single‐source supplier: Because they do other types of heat exchangers, you might streamline vendor management if you have related needs.

Things to Check / Questions to Ask

Before placing an order, good practice would include:

- Material of construction: What metals/tubesheets are used? Are they compatible with your oil, operating temperatures and pressures?

- Design codes & standards: Are the shell & tube oil coolers designed per recognized standards (TEMA, ASME, etc)?

- Thermal performance data: What is the rated oil inlet/outlet temperature, flow rate, ambient conditions?

- Testing & quality checks: Do they perform hydrostatic or pneumatic testing? Are test certificates provided?

- Lead time & installation support: What is the manufacturing lead time? Do they assist with installation, start‐up or service?

- Spare parts / service availability: How easy will it be to get spares or service locally in Karnataka/India?

Future Outlook

The thermal‐management sector in India is witnessing growth (especially as industrialisation, power generation, renewables and automotive sectors expand). According to industry reports, the heat‐exchanger market is competitive and growing. Our Manufacturing Based in Karnataka.

Conclusion

For organisations looking for shell & tube oil coolers in Karnataka—and more broadly in India—Maxflow Heat Exchangers presents a compelling choice. They combine localized production, broad product capabilities, and quality credentials. If you have oil cooling requirements (hydraulic, lubrication, process‐oil, etc), engaging with Maxflow could yield a tailored, efficient solution with support close at hand.